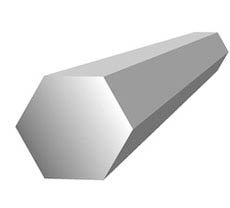

Inconel 600 Round Bars, Inconel UNS N06600 Hex Bars, ASTM B166 Inconel 600 Round Bars, Alloy 600 Round Bars, 600 Inconel Polished Bar, Inconel 600 Din 2.4816 Square Bars, Inconel 600 Round Bars suppliers in India

Triton Alloys Inc. is one of the leading supplier and exporter of Inconel 600 Round Bars, made from high-quality standard raw materials and manufactured to meet national and international requirements. Alloy 600 Bars is only one of the specialty steels on our premises. These UNS N06600 Round Bars are available in a range of shapes and sizes, just like most of the items we sell. Alloy 600 Round Bars are the nickel-chromium alloy, high oxidation resistance, and chloride-ion stress-corrosion, high-purity water corrosion, and caustic corrosion resistance. UNS N06600 Round Bars also has exceptional mechanical properties and high strength and excellent workability that are attractive.

Alloys heat treatment should be carried out by solution for the Inconel 600 Flat Bar at 1010 ° C or 1850 ° F for 15 minutes, then by cold air, with fresh air. Inconel 600 Rods must be supplied in the interval 1232 ° C -1038 ° C.Since there is low flexibility between 649 ° C and 871 ° C, hot working at that temperature range should be a.a. ASME SB 166 N06600 Flat Bar is expected to be a low ductility level. These WNR 2.4816 Bars are used for furnace parts, in nuclear engineering and for the sparking electrodes, in chemical and food processing, etc. Inconel 600 bars products are available at an affordable and market leading price, with specific shapes and sizes as requested by our customers.

Specification :

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | 5 mm To 500 mm |

| Diameter | 0.1 mm to 100 mm |

| Length | 100 mm To 6000 mm Long & Above |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Form | Round, Square, Hex (A/F),Flate, Rectangle, Billet, Ingot, Forging Etc. |

| Stainless Steel | ASTM A-479, A-182, 304, 304L,304H,304S, 316, 316L,316 Ti, 316H, 309, 310, 310S, 317L, 321, 347, 409, 410, 420, 430, 440, 446, 904L. etc. |

| Duplex Steel | 2205, 31803, 32750, 32760, 2101, 2304. |

| Alloy Steel | A-182 - F5, F9, F11, F12, F21, F22 & F91 |

| Special Grade | Stainless Steel 17-4 PH, Alloy 800, Alloy 600. Hastelloy C276. |

| Carbon Steel | A 105, LF 2, Duplex Steel. |

Inconel 600 Bar Equivalent Grades

|

STANDARD

|

WERKSTOFF NR.

|

UNS

|

JIS

|

BS

|

GOST

|

AFNOR

|

EN

|

|

Inconel 600

|

2.4816

|

N06600

|

NCF 600

|

NA 13

|

МНЖМц 28-2,5-1,5

|

NC15FE11M

|

NiCr15Fe

|

Inconel 600 Bar Chemical Composition

|

Grade

|

C

|

Mn

|

Si

|

Cu

|

S

|

Fe

|

Mo

|

Ni

|

Cr

|

|

Inconel 600

|

0.15 max

|

1 max

|

0.50 max

|

0.50 max

|

0.15 min

|

6.0-10.0

|

–

|

72 min

|

14.0–17.0

|

Inconel 600 Bar Mechanical Properties

|

Density

|

Melting Point

|

Tensile Strength

|

Yield Strength (0.2%Offset)

|

Elongation

|

|

8.47 g/cm3

|

1413 °C (2580 °F)

|

Psi – 95,000 , MPa – 655

|

Psi – 45,000 , MPa – 310

|

40 %

|

Ready Stock Available of Inconel 600 Round Bar

| Inconel 600 Square Bar | UNS N06600 Inconel Rectangular Bars | WERKSTOFF NR. 2.4816 Rectangular Bar |

| 600 Inconel Alloy Rectangular Bar | UNS N06600 Inconel Forged Rod | ASTM B166 600 Inconel Rectangular Bar |

| Inconel 600 Shaft | WERKSTOFF NR. 2.4816 Bright Bar | ASTM B166 600 Inconel Hex Bar |

| 600 Inconel Hexagonal Bar | 600 Inconel Alloy Hex Bar | UNS N06600 Inconel Triangle bar |

| UNS N06600 Inconel Hexagonal Bar | 600 Inconel Alloy Flat Bars | WERKSTOFF NR. 2.4816 Flat Bars |

| Inconel 600 Bright Bar | 600 Inconel Square Bars | ASTM B166 600 Inconel Flat Bars |

| 600 Inconel Alloy Square Bar | 600 Inconel Polished Bars | Inconel 600 Polished Bar |

| WERKSTOFF NR. 2.4816 Square Bar | 600 Inconel Threaded Bars | UNS N06600 Inconel Square Bar |

| Inconel 600 Rectangular Bar | 600 Inconel Rectangular Bars | UNS N06600 Inconel Polished Bars |

| UNS N06600 Inconel Bright Bar | Inconel Alloy 600 Bright Bar | WERKSTOFF NR. 2.4816 Polished Bar |

Types of Round Bar Available

Round Bar

Square Bar

Flat Bar

Hex Bar

Triangle Bar

Hollow Bar

Marking & Packing

Our Nickel Alloy 2.4066 round bars are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All Nickel Alloy UNS N02200 bar are marked with Grade, Lot No, Size and our trade mark. We can also make custom marking on our products on Special request from Purchaser.

Quality Assurance

Triton Alloys Inc all Nickel Alloy 200 round bars, Nickel Alloy 200 bright bars and Nickel 200 hex bars are subject to strict inspection at each stage starting from material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, DIN, EN, and JIS codes and standards. We can also appoint official certified Inspection Agencies upon request of our clients so that they can witness the material reports, dimensions and quality conformity of products.

India, Saudi Arabia, Bangladesh, United States, United Arab Emirates, Canada, Angola, Argentina, Austria, Azerbaijan, Pakistan, Peru, Chile, Spain, France, United Kingdom, Indonesia, Israel, Iran, Kuwait, Mexico, Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile, Venezuela, Ecuador, Netherlands, Brazil, Colombia, Ghana, Iran, Denmark, Poland, Australia, Afghanistan, Bahrain, Costa Rica, Egypt, Iraq, Jordan, South Korea, Kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Poland, Qatar, Russia, Vietnam, South Africa, Nigeria, Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Bolivia, Bulgaria, Croatia, Czech Republic, Estonia, Finland, Greece, Italy, Japan, Libya, Romania, Thailand, Trinidad & Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya, Lebanon, Morocco, Mongolia

Mumbai, Thane, Navi Mumbai, Pune, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, New Delhi, Bengaluru, Chennai, Surat, Bhopal, Ulsan, Faridabad, Houston, Dubai, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, London, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Muscat, Edmonton, Busan, Mexico City, Doha, Jeddah, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Melbourne, Madrid, La Victoria, Bogota, Lahore, Los Angeles, Algiers, Chiyoda, Ankara, Ho Chi Minh City, Toronto, Hong Kong, Rajkot, Brisbane, Petaling Jaya, Ernakulam, Secunderabad, Gimhae-si, Al Jubail, Port-of-Spain, Thiruvananthapuram, Milan, Atyrau, Lagos, Hanoi, Howrah, Sydney, Ahvaz, Karachi, New York, Caracas, Vung Tau, Al Khobar, Manama, Montreal, Granada, Courbevoie, Visakhapatnam, Ludhiana, Moscow, Dallas, Haryana, Colombo