S355J2H Hot Finish Circular Pipe, Hot Finish EN 10210 S355J2H ERW SHS Tubing, EN 10210 S355J2H Hot Finish Circular Tube, EN 10210 S355J2H CS Cold Formed Square Hollow Section, S355J2H Cold Formed CHS Tube, Cold Formed S355J2H CS SHS Tube, S355J2H Cold Formed Square Pipe.

To create the square hollow section pipes of grade S355J2H, a cold-formed sheet, which is welded at its ends, is used in a room-temperature process. The inner weld can be smoothed or deleted using technical options; the exterior weld is frequently treated. The major benefits of employing this type of square section pipe are the affordable fabrication of square, circular, or rectangular pipes for any material. Cold Formed square hollow structures ensure higher yield strength and improved mechanical resistance. Numerous industrial uses have benefited from its reduced surface and useful inside area, such as wires, cables, concrete, etc.

Due to its ease in meeting the needs of industrial applications, rectangular hollow sections produced of fine-grain steel grade S355J2H are in great demand. Due to its adaptable form and other positive traits, it is widely employed across many sectors. Consumers may find better static qualities in this cold-produced hollow segment. Additionally, it is advantageous because of its lighter structures, reduced resistance to water and air, and superb visual effects. The wall thickness of the pipe ranges from 0.5mm to 25mm. The standard specification of this hollow section is BS EN 10219.

Some of the circular hollow section sizes that are readily accessible vary from 21.3 to 42.4 mm in outer diameter, with a length of 6 to 7.5 meters. This length may be increased to 10 meters, and the diameter is 508 mm. The surface of these hollow sections is black, pre-galvanized and oil coating. Since these sections have low carbon, they have good corrosion resistance and can be used even at extreme temperatures. Civil engineering and construction employ this cold-formed circular hollow section for fixed load-bearing constructions. They are also used in offshore construction and platforms. The stiffness of these sections is also better than solids.

Specification :

| Standard | BS EN 10210 |

| Size | 20*20mm-400*400mm |

| Wall Thickness | 0.5mm - 25mm |

| Length | 6000-14000 mm |

| Type | Seamless/ Welded / ERW |

| Dimensional Tolerances | Thickness : (All sizes +/- 10%) |

| Packing | In bundles, Anticorrosion heat preservation, Varnish coating, Ends can be bevelled or square cut, End Capped Certification & supplementary test, Finishing & Identity Mark |

| Available Grades | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355J2+N, IS 4923 / ASTM A500 / As Per Requirement |

| Surface Protection | Black (Self Coloured uncoated), Varnish/Oil Coating, Pre-Galvanized, Hot Dip Galvanized |

Chemical Composition of S355J2H Hollow Section

| Grade | C | Si | Mn | P | S |

| S355J2H (1.0576) | 0.22 max | 0.55 max | 1.6 max | 0.03 max | 0.03 max |

Mechanical Properties of S355J2H Hollow Section

| Specification | Tensile Strength Rm N/mm2: 3 ≤ T ≤ 100mm | Yield Strength ReH Min, N/mm2: T ≤ 16mm | Min Elongation % T ≤ 40mm on gauge length 5.65. √S0 | Impact properties Minimum Ave energy (J) at -20°C |

| EN10210 S355J2H | 470 – 630 | 355 | 22 | 27 |

Types of Hollow Section Available

EN 10210 S355J2H Square Hollow Section

EN 10210 S355J2H Rectangular Hollow Section

EN 10210 S355J2H Circular Hollow Section

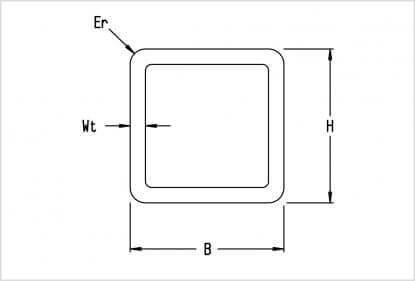

Dimensions of S355J2H Square Hollow Section

HxB – Height x Base

Wt – Wall thickness

Kg/m – Kilos per linear metre

Er – External radius

L – Standard bar length

| Size mm | kg/m | Size mm | kg/m |

| 20 x 20 x 2.0 | 1.12 | 20 x 20 x 2.5 | 1.35 |

| 25 x 25 x 1.5 | 1.06 | 25 x 25 x 2.0 | 1.43 |

| 25 X 25 X 2.5 | 1.74 | 25 X 25 X 3.0 | 2.04 |

| 30 X 30 X 2.0 | 1.68 | 30 X 30 X 2.5 | 2.14 |

| 30 X 30 X 3.0 | 2.51 | 40 x 40 x 1.5 | 1.81 |

| 40 x 40 x 2.0 | 2.31 | 40 x 40 x 2.5 | 2.92 |

| 40 x 40 x 3.0 | 3.45 | 40 x 40 x 4.0 | 4.46 |

| 40 x 40 x 5.0 | 5.40 | 50 x 50 x 1.5 | 2.28 |

| 50 x 50 x 2.0 | 2.93 | 50 x 50 x 2.5 | 3.71 |

| 50 x 50 x 3.0 | 4.39 | 50 x 50 x 4.0 | 5.72 |

| 50 x 50 x 5.0 | 6.97 | 60 x 60 x 3.0 | 5.34 |

| 60 x 60 x 4.0 | 6.97 | 60 x 60 x 5.0 | 8.54 |

| 60 x 60 x 6.0 | 9.45 | 70 x 70 x 3.0 | 6.28 |

| 70 x 70 x 3.6 | 7.46 | 70 x 70 x 5.0 | 10.11 |

| 70 x 70 x 6.3 | 12.50 | 70 x 70 x 8 | 15.30 |

| 75 x 75 x 3.0 | 7.07 | 80 x 80 x 3.0 | 7.22 |

| 80 x 80 x 3.6 | 8.59 | 80 x 80 x 5.0 | 11.70 |

| 80 x 80 x 6.0 | 13.90 | 90 x 90 x 3.0 | 8.01 |

| 90 x 90 x 3.6 | 9.72 | 90 x 90 x 5.0 | 13.30 |

| 90 x 90 x 6.0 | 15.76 | 90 x 90 x 8.0 | 20.40 |

| 100 x 100 x 3.0 | 8.96 | 100 x 100 x 4.0 | 12.00 |

| 100 x 100 x 5.0 | 14.80 | 100 x 100 x 5.0 | 14.80 |

| 100 x 100 x 6.0 | 16.19 | 100 x 100 x 8.0 | 22.90 |

| 100 x 100 x 10 | 27.90 | 120 x 120 x 5 | 18.00 |

| 120 x 120 x 6.0 | 21.30 | 120 X 120 X 6.3 | 22.30 |

| 120 x 120 x 8.0 | 27.90 | 120 x 120 x 10 | 34.20 |

| 120 X 120 X 12 | 35.8 | 120 X 120 X 12.5 | 41.60 |

| 140 X 140 X 5.0 | 21.10 | 140 X 140 X 6.3 | 26.30 |

| 140 X 140 X 8 | 32.90 | 140 X 140 X 10 | 40.40 |

| 140 X 140 X 12.5 | 49.50 | 150 X 150 X 5.0 | 22.70 |

| 150 X 150 X 6.3 | 28.30 | 150 X 150 X 8.0 | 35.40 |

| 150 X 150 X 10 | 43.60 | 150 X 150 X 12.5 | 53.40 |

| 150 X 150 X 16 | 66.40 | 150 X 150 X 16 | 66.40 |

| 180 X 180 X 5 | 27.40 | 180 X 180 X 6.3 | 34.20 |

| 180 X 180 X 8 | 43.00 | 180 X 180 X 10 | 53.00 |

| 180 X 180 X 12.5 | 65.20 | 180 X 180 X 16 | 81.40 |

| 200 X 200 X 5 | 30.50 | 200 X 200 X 6 | 35.8 |

| 200 x 200 x 6.3 | 38.2 | 200 x 200 x 8 | 48.00 |

| 200 x 200 x 10 | 59.30 | 200 x 200 x 12.5 | 73.00 |

| 200 x 200 x 16 | 91.50 | 250 x 250 x 6.3 | 48.10 |

| 250 x 250 x 8 | 60.50 | 250 x 250 x 10 | 75.00 |

| 250 x 250 x 12.5 | 92.60 | 250 x 250 x 16 | 117.00 |

| 300 x 300 x 6.3 | 57.90 | 300 x 300 x 8 | 73.10 |

| 300 x 300 x 10 | 57.90 | 300 x 300 x 8 | 90.70 |

| 300 x 300 x 12.5 | 112.00 | 300 x 300 x 16 | 142.00 |

| 350 x 350 x 8 | 85.70 | 350 x 350 x 10 | 106.00 |

| 350 x 350 x 12.5 | 132.00 | 350 x 350 x 16 | 167.00 |

| 400 x 400 x 10 | 122.00 | 400 x 400 x 12 | 141.00 |

| 400 x 400 x 12.5mm | 152.00 | 400 x 400 x 16 | 192 |

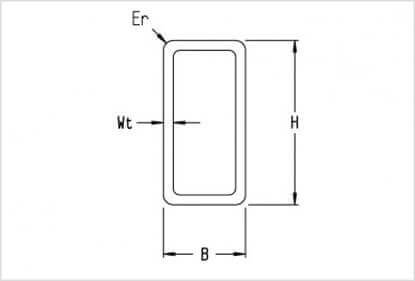

Dimensions of S355J2H Rectangular Hollow Section

HxB – Height x Base

Wt – Wall thickness

Kg/m – Kilos per linear metre

Er – External radius

L – Standard bar length

| Size mm | kg/m | Size mm | kg/m |

| 40 x 20 x 2.0 | 1.68 | 40 x 20 x 2.5 | 2.03 |

| 40 x 20 x 3.0 | 2.36 | 40 x 25 x 1.5 | 1.44 |

| 40 x 25 x 2.0 | 1.89 | 40 x 25 x 2.5 | 2.23 |

| 50 x 25 x 2.0 | 2.21 | 50 x 25 x 2.5 | 2.72 |

| 50 x 25 x 3.0 | 3.22 | 50 x 30 x 2.5 | 2.92 |

| 50 x 30 x 3.0 | 3.45 | 50 x 30 x 4.0 | 4.46 |

| 50 x 40 x 3.0 | 3.77 | 60 x 40 x 2.0 | 2.93 |

| 60 x 40 x 2.5 | 3.71 | 60 x 40 x 3.0 | 4.39 |

| 60 x 40 x 4.0 | 5.72 | 70 x 50 x 2 | 3.56 |

| 70 x 50 x 2.5 | 4.39 | 70 x 50 x 3.0 | 5.19 |

| 70 x 50 x 4.0 | 6.71 | 80 x 40 x 2.5 | 4.26 |

| 80 x 40 x 3.0 | 5.34 | 80 x 40 x 4.0 | 6.97 |

| 80 x 40 x 5.0 | 8.54 | 80 x 50 x 3.0 | 5.66 |

| 80 x 50 x 4.0 | 7.34 | 90 x 50 x 3.0 | 6.28 |

| 90 x 50 x 3.6 | 7.46 | 90 x 50 x 5.0 | 10.11 |

| 100 x 50 x 2.5 | 5.63 | 100 x 50 x 3.0 | 6.75 |

| 100 x 50 x 4.0 | 8.86 | 100 x 50 x 5.0 | 10.90 |

| 100 x 60 x 3.0 | 7.22 | 100 x 60 x 3.6 | 8.59 |

| 100 x 60 x 5.0 | 11.70 | 120 x 80 x 2.5 | 7.65 |

| 120 x 80 x 3.0 | 9.03 | 120 x 80 x 4.0 | 12.00 |

| 120 x 80 x 5.0 | 14.80 | 120 x 80 x 6.0 | 17.60 |

| 120 x 80 x 8.0 | 22.9 | 150 x 100 x 5.0 | 18.70 |

| 150 x 100 x 6.0 | 22.30 | 150 x 100 x 8.0 | 29.10 |

| 150 x 100 x 10.0 | 35.70 | 160 x 80 x 5.0 | 18.00 |

| 160 x 80 x 6.0 | 21.30 | 160 x 80 x 8.0 | 27.90 |

| 200 x 100 x 5.0 | 22.70 | 200 x 100 x 6.0 | 27.00 |

| 200 x 100 x 8.0 | 35.4 | 200 x 100 x 10.0 | 43.60 |

| 250 x 150 x 5.0 | 30.5 | 250 x 150 x 6.0 | 38.2 |

| 250 x 150 x 8.0 | 48.0 | 250 x 150 x 10 | 59.3 |

| 300 x 200 x 6.0 | 48.10 | 300 x 200 x 8.0 | 60.50 |

| 300 x 200 x 10.0 | 75.00 | 400 x 200 x 8.0 | 73.10 |

| 400 x 200 x 10.0 | 90.70 | 400 x 200 x 16 | 142.00 |

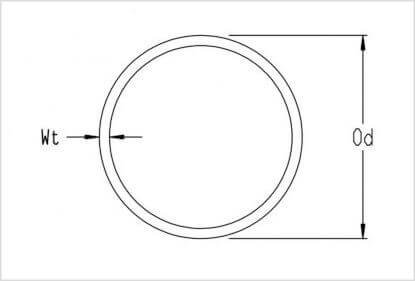

Dimensions of S355J2H Circular Hollow Section

Od – Outside diameter

Wt – Wall thickness

Kg/m – Kilos per linear metre

L – Standard bar length

| Nominal Bore | Outside diameter | Thickness | Weight |

| mm | mm | mm | kg/m |

| 15 | 21.3 | 2.00 | 0.95 |

| 2.60 | 1.21 | ||

| 3.20 | 1.44 | ||

| 20 | 26.9 | 2.30 | 1.38 |

| 2.60 | 1.56 | ||

| 3.20 | 1.87 | ||

| 25 | 33.7 | 2.60 | 1.98 |

| 3.20 | 0.24 | ||

| 4.00 | 2.93 | ||

| 32 | 42.4 | 2.60 | 2.54 |

| 3.20 | 3.01 | ||

| 4.00 | 3.79 | ||

| 40 | 48.3 | 2.90 | 3.23 |

| 3.20 | 3.56 | ||

| 4.00 | 4.37 | ||

| 50 | 60.3 | 2.90 | 4.08 |

| 3.60 | 5.03 | ||

| 5.00 | 6.19 | ||

| 65 | 76.1 | 3.20 | 5.71 |

| 3.60 | 6.42 | ||

| 4.50 | 7.93 | ||

| 80 | 88.9 | 3.20 | 6.72 |

| 4.00 | 8.36 | ||

| 4.80 | 9.90 | ||

| 100 | 114.3 | 3.60 | 9.75 |

| 4.50 | 12.20 | ||

| 5.40 | 14.50 | ||

| 125 | 139.7 | 4.50 | 15.00 |

| 4.80 | 15.90 | ||

| 5.40 | 17.90 | ||

| 150 | 165.1 | 4.50 | 17.80 |

| 4.80 | 18.90 | ||

| 5.40 | 21.30 | ||

| 150 | 168.3 | 5.00 | 20.1 |

| 6.3 | 25.2 | ||

| 8.00 | 31.6 | ||

| 10.00 | 39 | ||

| 12.5 | 48 | ||

| 200 | 219.1 | 4.80 | 25.38 |

| 6.00 | 31.51 | ||

| 8.00 | 41.67 | ||

| 10.00 | 51.59 | ||

| 250 | 273 | 6.00 | 39.51 |

| 8.00 | 52.30 | ||

| 10.00 | 64.59 | ||

| 300 | 323.9 | 6.30 | 49.36 |

| 8.00 | 62.35 | ||

| 10.00 | 77.44 |

Available Hollow Section

Hot Finish S355J2H Seamless Square Hollow Section

S355J2H Hot Finish Welded Square Hollow Section

S355J2H Cold Formed Square Hollow Section Welded Tube

S355J2H Cold Formed RHS

EN 10210 S355J2H Rectangular Hollow Section

EN 10210 S355J2H Seamless Rectangular Hollow Section

EN 10210 S355J2H Seamless Hot Finish Circular Hollow Section Tubing

S355J2H Hot Finish Circular Pipe

S355J2H Cold Formed CHS Tube

Price List of S355J2H Piping

| Carbon Steel S355J2H Seamless Pipe manufacturer US / Metric Ton (FOB Price) on request |

BS EN 10210 S355J2H Carbon Steel Pipes US / Metric Ton (FOB Price) on request |

| EN 10210 S355J2H Carbon Steel Structural Pipe US / Metric Ton (FOB Price on request |

Grade S355J2H Seamless Pipe US / Metric Ton (FOB Price) on request |

| S355J2H Cold Drawn Seamless Pipes US / Ton (FOB Price) on request |

S355J2H Steel Seamless Pipe US / Ton (FOB Price) on request |

| S355J2H Carbon Steel Seamless Square Pipe US / Ton (FOB Price) on request |

S355J2H Carbon Steel Seamless Rectangular Pipes US / Ton (FOB Price) on request |

| S355J2H Carbon Steel Seamless Round Pipes US / Ton (FOB Price) on request |

S355J2H Hot Finished Seamless Pipes US / Ton (FOB Price) on request |

Pipes & Tubes Applications Industries

S355J2H Seamless Pipe are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Buttweld Degree Forged through a worldwide network of stock-keeping branches. Buttweld Forged is use in various industries like :

- Pipes & Tubes uses in Paper & Pulp Companies

- Pipes & Tubes uses in Oil and Gas Industry

- Pipe Forged uses in Chemical Refinery

- Buttweld Pipe Forged uses in High Temperature Application

- Pipes & Tubes uses in Water Pipe Line

- Pipe Forged can be used in Nuclear power plants

- Pipes & Tubes usefule for High Pressure Applications

- Pipes & Tubes Long Radius Forged uses in Fabrication and welding Job

- Pipes & Tubes uses in Food Processing and Dairy Industries

- Pipes & Tubes Short Radius Forged uses in boiler & heatexchangers

Marking & Packing

Our S355J2H Seamless Pipe are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All EN 10210 S355J2H Carbon Steel Pipe are marked with Grade, Lot No, Size and our trade mark. We can also make custom marking on our products on Special request from Purchaser.

Quality Assurance

Triton Alloys Inc all En 10210 Pipe, S355J2H EN 10219 Welded Pipe and S355j2h Hot Rolled Rectangular Pipe are subject to strict inspection at each stage starting from material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, DIN, EN, and JIS codes and standards. We can also appoint official certified Inspection Agencies upon request of our clients so that they can witness the material reports, dimensions and quality conformity of products.

India, Saudi Arabia, Bangladesh, United States, United Arab Emirates, Canada, Angola, Argentina, Austria, Azerbaijan, Pakistan, Peru, Chile, Spain, France, United Kingdom, Indonesia, Israel, Iran, Kuwait, Mexico, Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile, Venezuela, Ecuador, Netherlands, Brazil, Colombia, Ghana, Iran, Denmark, Poland, Australia, Afghanistan, Bahrain, Costa Rica, Egypt, Iraq, Jordan, South Korea, Kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Poland, Qatar, Russia, Vietnam, South Africa, Nigeria, Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Bolivia, Bulgaria, Croatia, Czech Republic, Estonia, Finland, Greece, Italy, Japan, Libya, Romania, Thailand, Trinidad & Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya, Lebanon, Morocco, Mongolia

Mumbai, Thane, Navi Mumbai, Pune, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, New Delhi, Bengaluru, Chennai, Surat, Bhopal, Ulsan, Faridabad, Houston, Dubai, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, London, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Muscat, Edmonton, Busan, Mexico City, Doha, Jeddah, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Melbourne, Madrid, La Victoria, Bogota, Lahore, Los Angeles, Algiers, Chiyoda, Ankara, Ho Chi Minh City, Toronto, Hong Kong, Rajkot, Brisbane, Petaling Jaya, Ernakulam, Secunderabad, Gimhae-si, Al Jubail, Port-of-Spain, Thiruvananthapuram, Milan, Atyrau, Lagos, Hanoi, Howrah, Sydney, Ahvaz, Karachi, New York, Caracas, Vung Tau, Al Khobar, Manama, Montreal, Granada, Courbevoie, Visakhapatnam, Ludhiana, Moscow, Dallas, Haryana, Colombo